Over 35 years experience, providing smoke flavour solutions to the food industry

Need innovative food, water and horticultural treatments?

SMOKING & BROWNING - FOOD INDUSTRY

Grayson Australia’s liquid smoke flavours are a direct result of condensing, clean wood smoke vapour with water via a closed loop manufacturing process, to produce a range of high quality smoke flavours without the emissions to atmosphere.

Additionally, liquid smoke has the benefit of acting as both an antioxidant and anti microbial agent, assisting in preserving food and extending shelf life.

ADVANTAGES COMPARED TO TRADITIONAL SMOKING

• Shorter production time and higher yields

• Greater consistency of colour and flavour

• Adjustable flavour and colour options

• No tar deposits in the smoking chamber

• Less cleaning costs

• No wood or open flame in production areas

• Reduced emissions and chemical use

• Extended shelf life

• Sustainably sourced

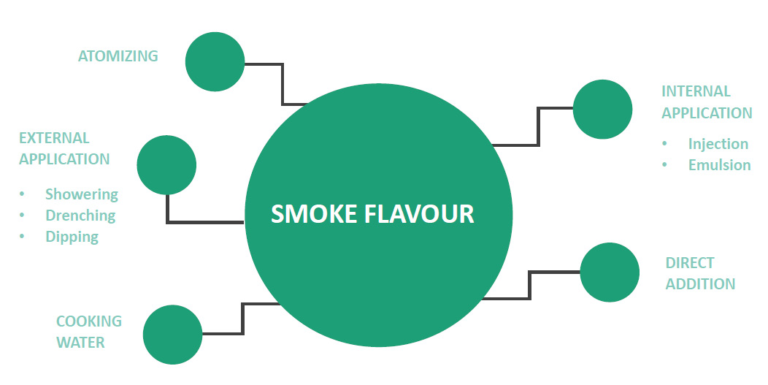

APPLICATION - SMOKE FLAVOUR

ATOMIZING LIQUID SMOKES

Atomizing with liquid smoke is a commercially viable option to replicate traditional smoking methods. Pressurised air is used to vaporize thecondensed liquid smoke to create the same smoke environment as a smokehouse, without burning actual wood.

This process is similar to traditional smoking, however offers a reduced processing time, greater flavour and colour consistency, while producing higher end yields, without emissions to atmosphere. These liquid smokes are suitable for applying to meat, seafood, poultry and vegan preparations.

Learn More

Application Rate:

100% undiluted

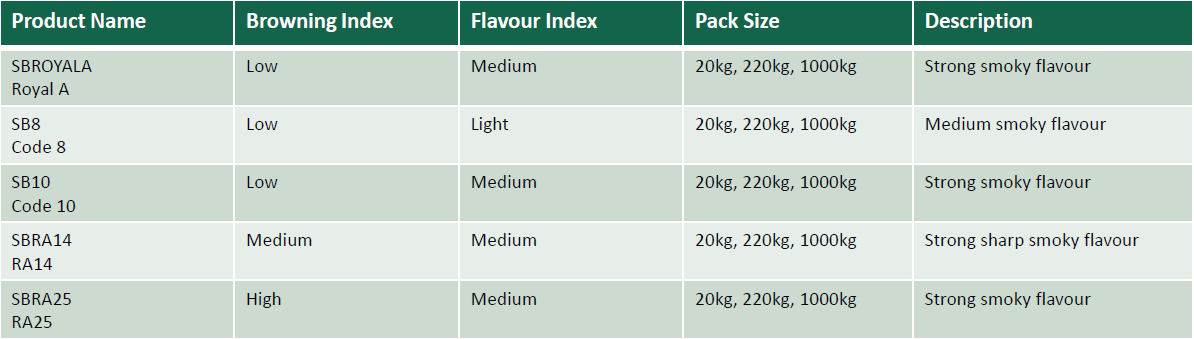

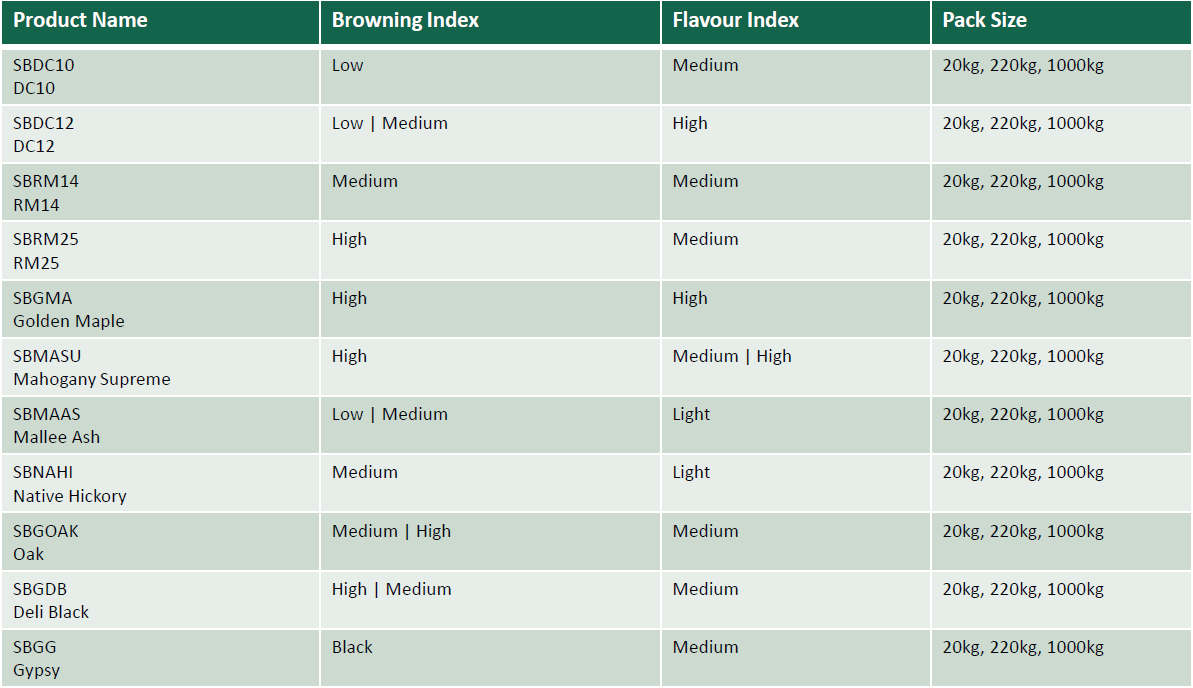

EXTERNAL APPLICATION - LIQUID SMOKES

External liquid smokes are highly economical and can be easily applied by showering, drenching or dipping, offering shorter processing times and a decrease in cook shrinkage. This method of application is environmentally friendly, providing opportunity to recycle and minimize the use of harsh chemicals.

These types of liquid smokes offer flavour, colour and preserving qualities, which can be tailored to meet specific product requirements. They are a suitable application for meat, poultry, seafood, jerky and vegan preparations.

Learn More

Application Rate:

1 part smoke to 2 parts water

INTERNAL APPLICATION - LIQUID SMOKES

Internal Liquid Smokes are highly effective when applied internally to increase smoke flavour consistency throughout the product and to ensure no premature loss of nitrates or effect on binding properties.

These types of liquid smokes are suitable for adding into emulsion, brines and sauces.

Learn More

Application Rate:

Emulsion: 0.2

0.5g per kg finished product

Injection: 1

2% by volume

DIRECT ADDITION - SMOKE FLAVOUR

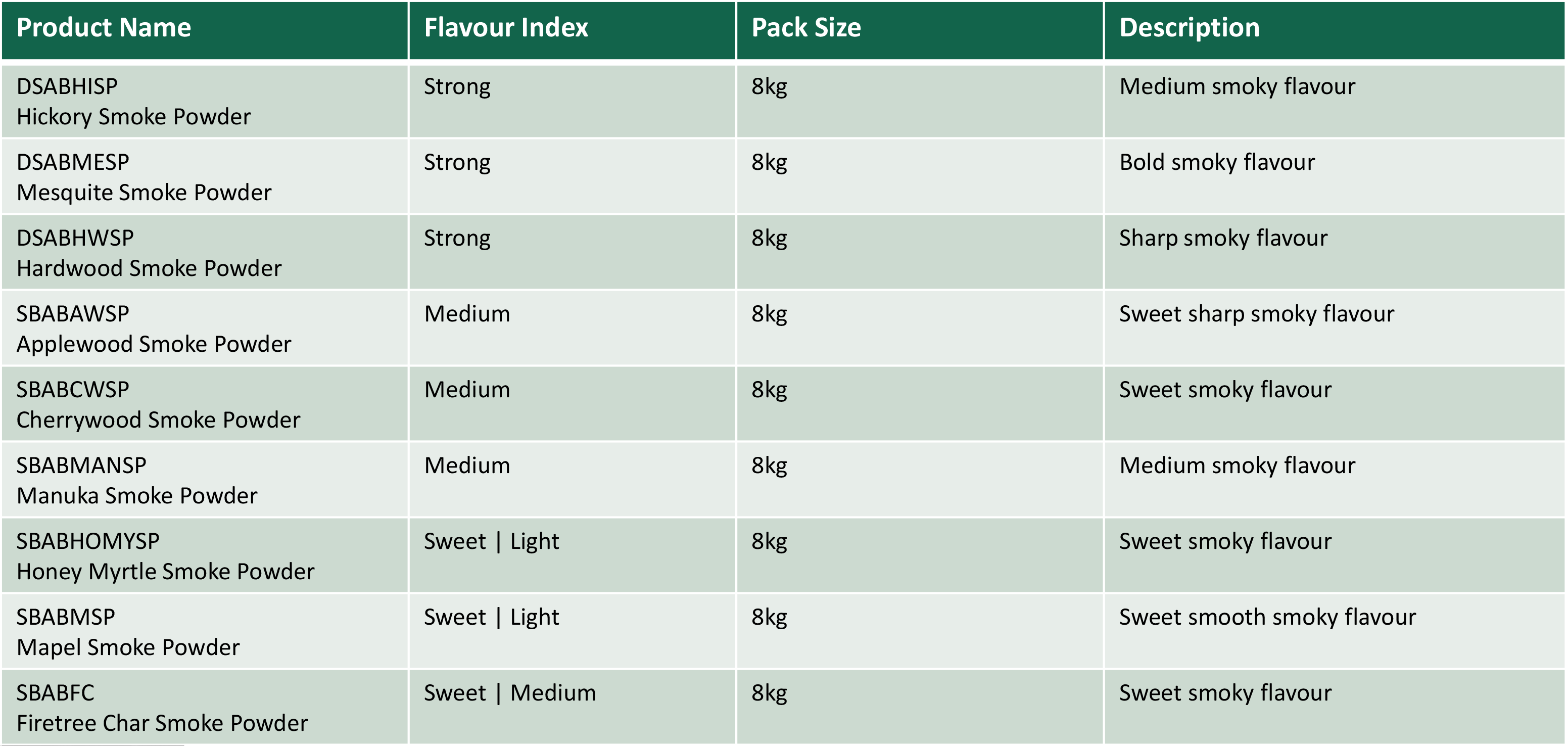

Smoke powders are ideal for enhancing the natural flavour of food and can be easily applied directly to the surface or into emulsion.

Smoke powders are also suitable for blending with snack seasonings, meat rubs, stuffing, dry curing mixes and vegan preparations.

Learn More

Application Rate:

Direct addition: 1.0 – 2.0g per kg finished product

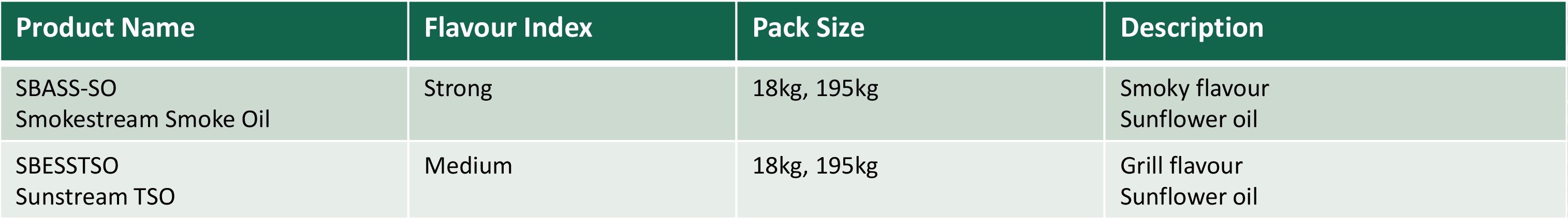

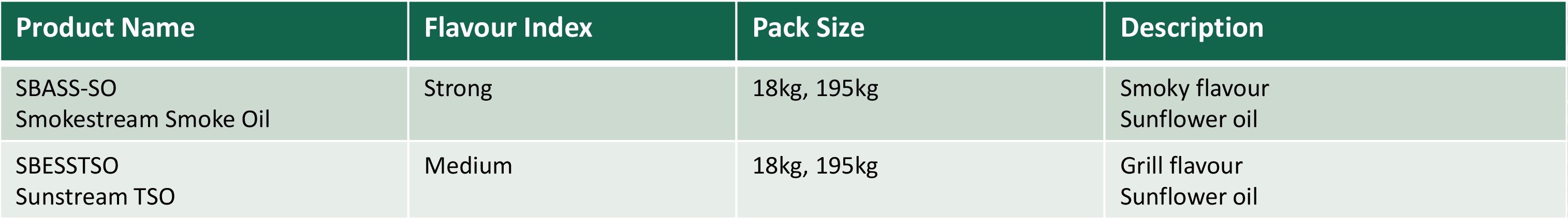

DIRECT ADDITION - SMOKE & GRILL OIL

Smoke and grill oils provide a smoky meat or grill flavour without the colour formation.

Both oils are suitable for applying to snack foods, cheese, dry sausage, canned fish, canned vegetable and any oil-based product.

Learn More

Application Rate:

Direct addition: 0.2 – 2.0g per kg finished product

BROWNING AGENTS

Browning agents offer products a rich golden roasted appearance without extensive cooking times or impacts to the flavour profile. Browning agents are a natural sugar base ingredient easily applied to the surface of poultry, roasted meats, breaded items, cheese, fish and microwaveable meals.

Benefits:

- Easy to apply

- Controlled and consistent colour

- Diverse range of cooking methods

Learn More

Application Rate:

Atomizing: 100% undiluted

Dipping & Drenching: Dilute 20-80% with water, dependant on desired colour formation

Spraying: Dilute 5-20% with water, depending on desired colour formation

Cooking Water: 5-10% added to the cooking water

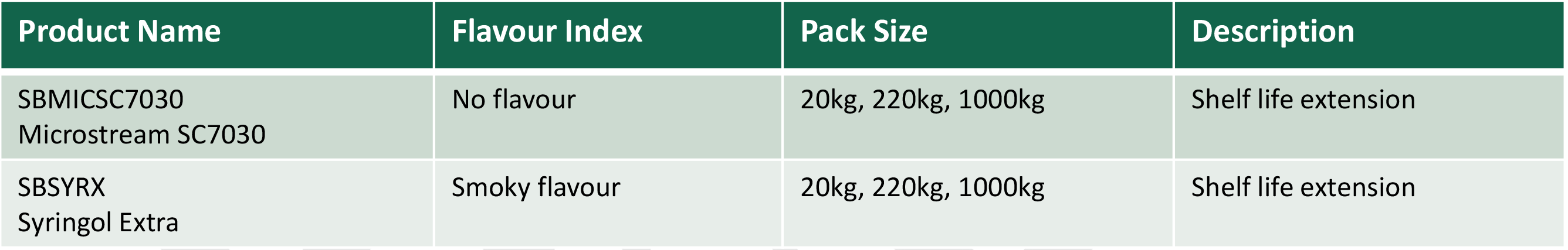

ANTI-MICROBIALS

Smoke and smoke flavourings have high anti-microbial properties against bacteria, mould and yeasts.

The various components in smoke can show various properties, but the average composition is very effective.

It is possible to dilute and isolate certain fractions with higher anti-microbial properties and at the same time lower the flavour impact if required. The flavour can be applied externally by atomizing, drenching and spraying or directly into packaging prior to sealing.

Learn More

Application Rate:

Spraying and Dipping: dilute 50% with water

Atomizing: 100% undiluted

Want a trial? Order a FREE sample*?